SQ-bar system (for indoors)

- >

- Products

- >

- SQ-bar system (for indoors)

SQ-bar system (for indoors)

SQ-bar is closed type Bar by shaping galvanized steel plate in a rectangular form. Accordingly it has excellent section property and after use it has resistance against deformity due to long-term load and also has resistance /durability against earthquake. It minimizes interference with air conditioning system inside of ceiling and bolts and is light weight frame in consideration of flexibility of works in connection with prior and post-works process.

- Product outline

- Product drawing

- Information for construction

- Miscellaneous

Outline of SQ-Bar System

SQ-bar is closed type Bar by shaping galvanized steel plate in a rectangular form. Accordingly it has excellent section property and after use it has resistance against deformity due to long-term load and also has resistance /durability against earthquake. It minimizes interference with air conditioning system inside of ceiling and bolts and is light weight frame in consideration of flexibility of works in connection with prior and post-works process.

SQ-bar system products

(1) Materials

- Quality of materials: KSD 3506 (melt zinc galvanized steel plate)

- KSD 3609 (Steel support material for construction)

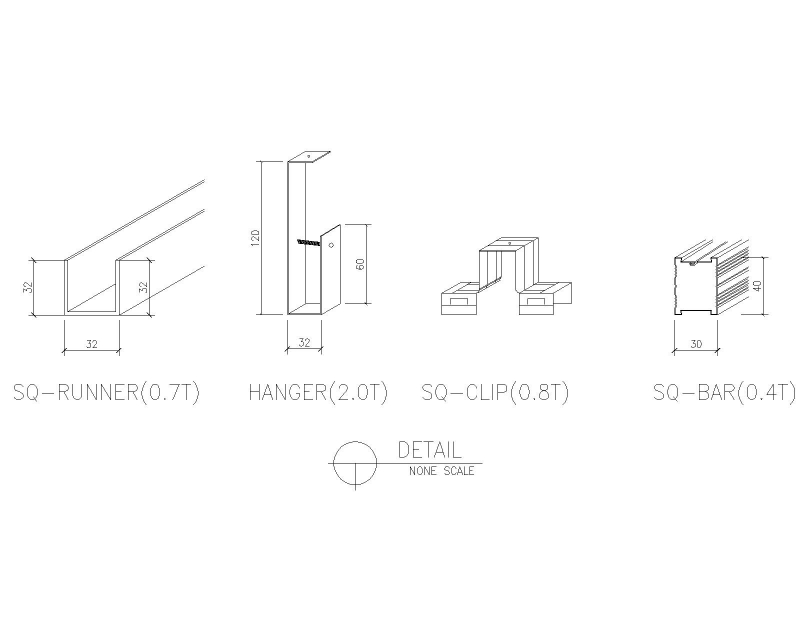

(2) Dimension

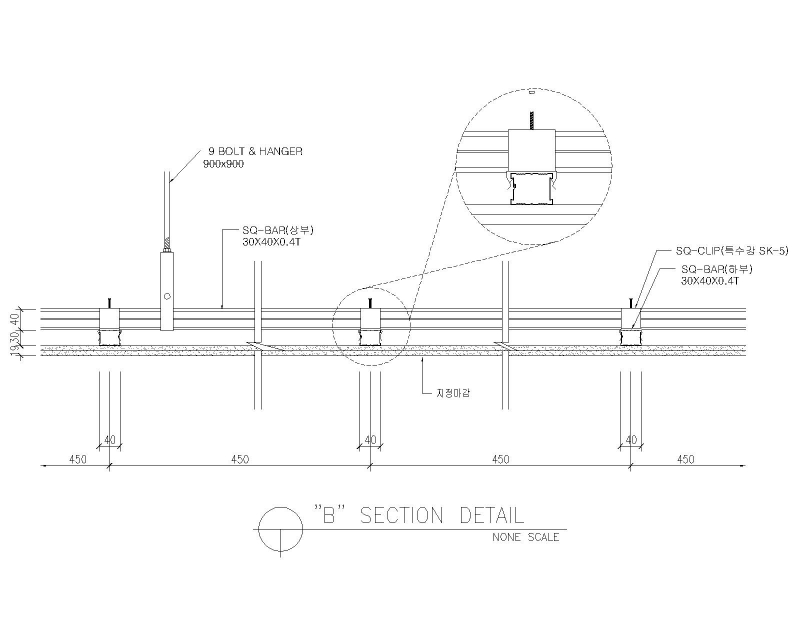

- upper part: 30x 40x 0.4T or above lower part; identical member as above

- ② HANGER BOLT : 9mm X 1,000

- ③ HANGER & BEES : 32X160X2.0T

- ④ HANGER NUT : ψ9

- ⑤ SQ-BAR JOINT : 0.6T

- ⑥ SQ-BAR CLIP & BEES : 0.8T

- ⑦ SQ-runner: 32x 40 x 0.6T or above.

- ⑧ ceiling hanger bracket: 1.0T or above, L=order length

- ⑨ molding: comply with drawing

Special feature of S-bar system

- * Minimizing interference with air-conditioning system by using SQ-bar.

- * Outstanding durability

- * Easy works by virtue of reduction of supplementary members

- * Suitable to heavy ceiling

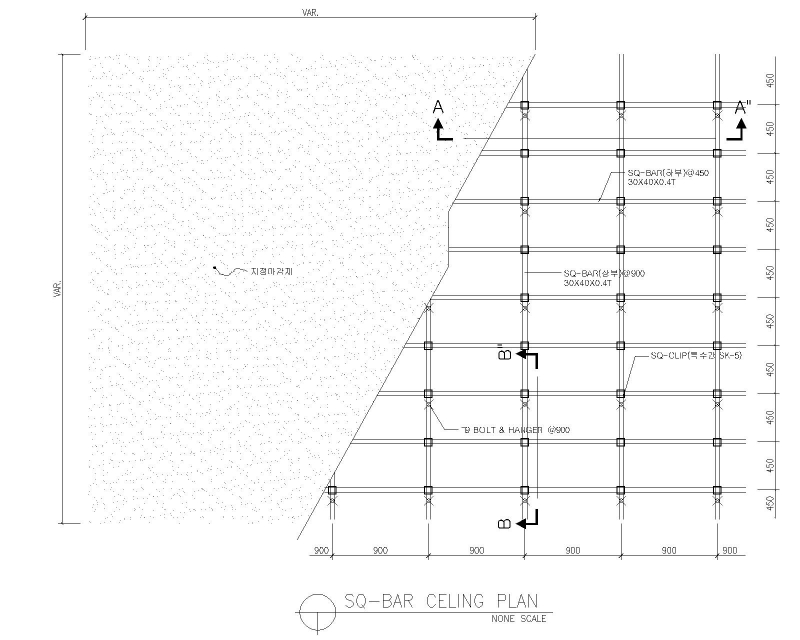

(1) Set up centerline of building; Set up center line by checking other work process such as light line and location of diffuser etc. after carrying out precise survey of ceiling.

(2) Molding line level check

- ① Using water level method or level

a. Confirming location according to drawing (confirming height of ceiling)

b. Confirming the location by water level and marking the space between points with India ink. - ② At the time of using water level first check whether or not any foam is present within hose or breaking of hose then carry out level check.

(3) Strong anchor work

- ① At the time for strong anchor work; When centerline is set mark the spot for fixing strong anchor (9mm) at slab face and drill hole then fix it.

- ② At the time of putting ceiling hanger bracket: It may substitute for strong anchor.

- ③ It is ideal to make interval for installation of strong anchor or insert as @900∼1,200 mm in consideration of direction of installing SQ-bar. ( In case of installing ceiling hanger bracket it shall comply with the drawing and unless otherwise provided it shall be installed within 2,000 mm.)

- ④ Caution: Pay attention to space and right angle between insert or strong anchor. After approval by supervisor it may be substituted by bullet.

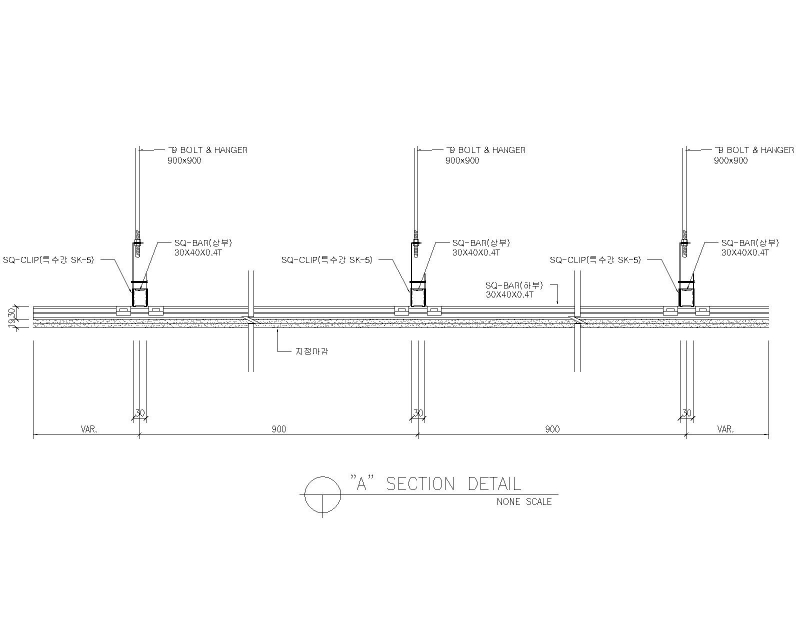

(4) Installing anchor bolt

- ① Fix the upper part of anchor bolt to strong anchor or insert and fix it with hanger and nut in consideration of ceiling height.

- ② At the place where installation duct and other obstacles are present work shall be carried out after reinforcementaccording to drawing and specification.

(5) Attachment of SQ-runner

- ① Attach SQ-runner along ink-pot string and SR-runner shall be fixed at an interval of @500∼1,000mm by using 1" concrete nail.

- ② Be careful not to slacken height and space between SQ-runner and SQ-runner.

- ③ Attach curtain box according to specification in connection with installed pieces.

- ④ Caution; If not indicated on the drawing SQ-runner may be omitted.

(6) Installation of lightline

- It shall be done according to specification for installation of lightline but consultation with persons related to electricity and installation shall be required.

(7) Installation of SQ-bar (upper part)

- Hanger set and SQ-bar are tied by piece and fixed and shall be installed within @1,200 mm.

- The connection part of SQ-bar shall be connected by SQ-bar joint.

- SQ-bar shall be installed in a way not to be away more than 30 cm from wall or curtain box side.

(8) Installation of SQ-bar (lower part)

- ① Install SQ-bar after placing string at centerline of the work sturdily by using SQ-bar clip with piece at right angle direction to SQ-bar (upper part) according to dimension of the product and along the light line.

- ② Installation interval of SQ-bar (lower part) shall comply with drawing or specification. When it is not recorded at drawing or specification then install it within 450 mm.

- ③ SQ-bar (lower part) shall be installed by inserting it to SQ-runner or curtain box wing.

- ④ Level of installed ceiling frame shall be maintained accurately by water level or using level.

- ⑤ Note: At the time of using ceiling hanger bracket then with approval from supervisor SQ-bar (upper part) may be omitted.

(10) Installation of finishing plate

- ① Finishing plate is fixed with piece to SQ-bar.

- ② Line of finishing plate shall be straight line and there shall be no gap at joint part.

- ③ Finishing place shall comply with drawing.

(11) Installation of curtain box

- ① Depending on specification products suitable to purpose is manufactured and installed. (separate painting)

- ② Welding work is carried out concurrently thus install work bench enabling work in safe and convenient stance.

(1) Handling and storage of the product

- ① Store it in a condition with relative humiditiy of 80% or less.

- ② To prevent any damage from water or moisture always keep it at dry and clean place.

- ③ Be careful not to damage corners

- ④ Maintain certain space from the wall surface and place spread sheet and then lay down water-proof sheet then preserve it.

(2) Environmental condition at the time of carrying out the works

- ① At the time of works temperature of 30℃ or less and relative humidity of 80% or less shall be maintained.

- ② The works shall be commenced after completion of joiners' works.

- ③ Before. during and after the works air-conditioners shall be operated so that proper level of indoors temperature and relative humidity are maintained.

- ④ The works shall be commenced after completion of all the papering and painting walls and ceiling.

(3) Caution at the time of carrying out works

- Pipe-layng and electric works shall be completed before installation of SQ-bar installation and then works shall be carried out.

(4) Conditions for carrying out works

- ① The contractor for the works shall consult with the client with sufficient consideration of site conditions.

- ② While carrying out works at the time of appearance of any problems works shall be continued after sufficient consultation with the client.

- ③ As much as possible ceiling plan intended by the designer shall be observed.