AL TORSION PANEL (flat panel type, sloped type, down type)

- >

- Products

- >

- AL TORSION PANEL (flat panel type, sloped type, down type)

AL TORSION PANEL (flat panel type, sloped type, down type)

Torsion panel which adopted vertical elastic and repellent fixed method can be easily attached and detached. It is designed quake-proof. It solves problem of destruction of combination parts due to upward, downward, left and right side vibration and falling off of metallic parts. It has structure enabling assurance of safety by preventing any accident in advance. It is highly functional ceiling metallic finishing material applicable to lobby and pilotti of public facilities being used by many people such as commercial/residential buildings and subways.

- Product outline

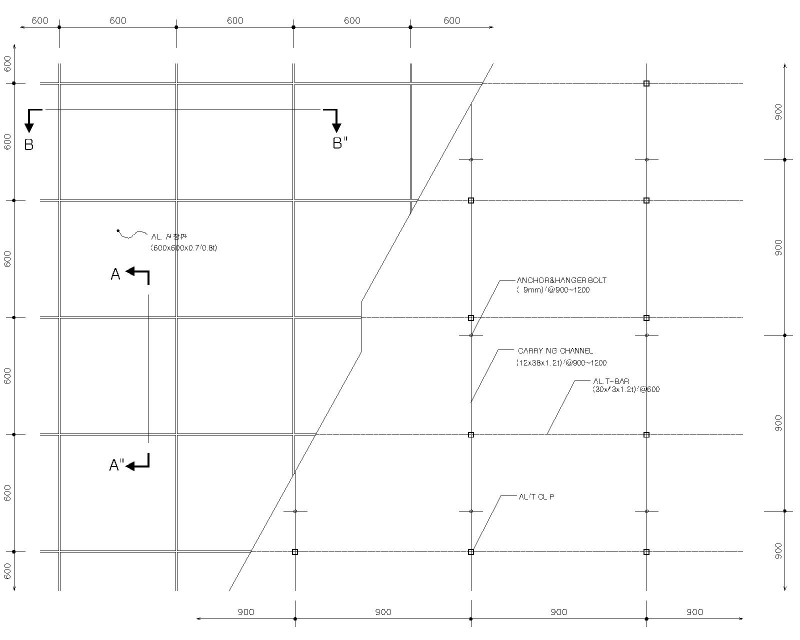

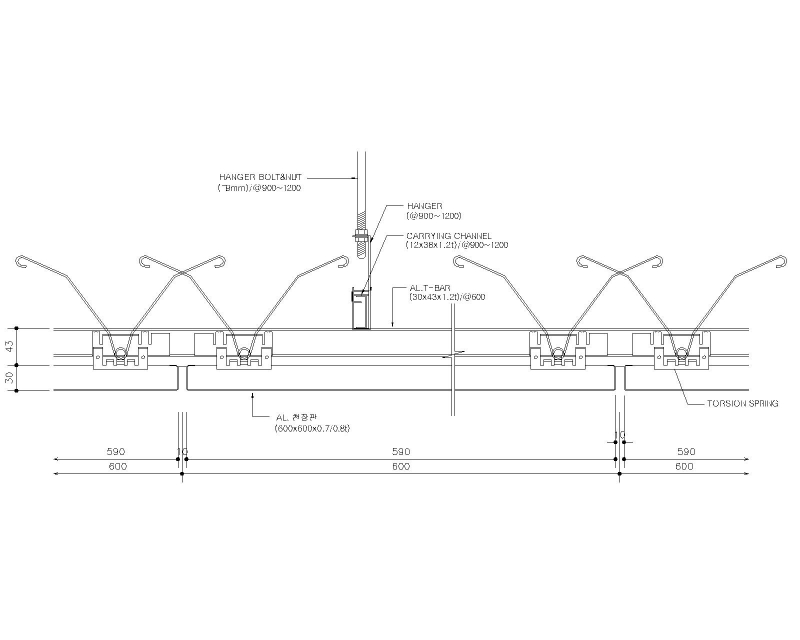

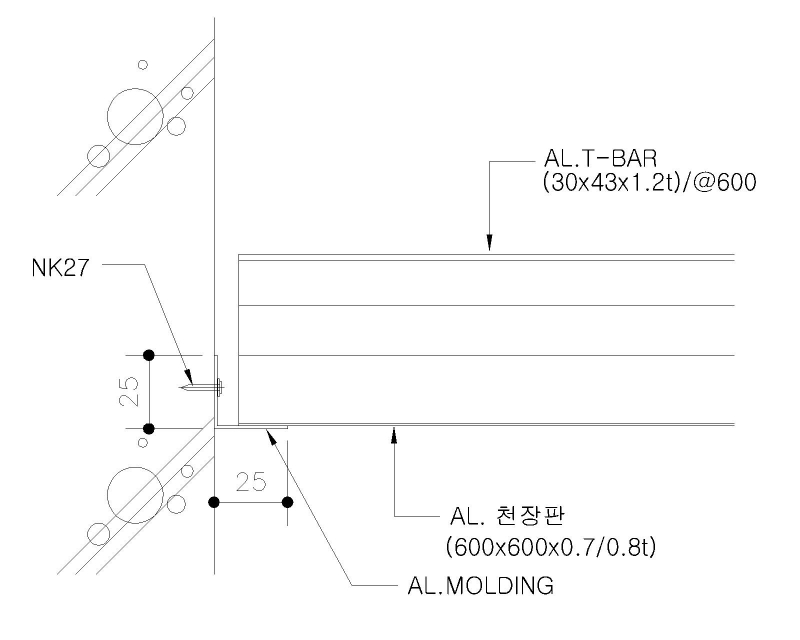

- Product drawing

- Information for construction

- Miscellaneous

Outline of Al Torsion Panel (flate type, slope type, down type)

Torsion panel which adopted vertical elastic and repellent fixed method can be easily attached and detached. It is designed quake-proof.It solves problem of destruction of combination parts due to upward, downward, left and right side vibration and falling off of metallic parts. It has structure enabling assurance of safety by preventing any accident in advance. It is highly functional ceiling metallic finishing material applicable to lobby and pilotti of public facilities being used by many people such as commercial/residential buildings and subways.

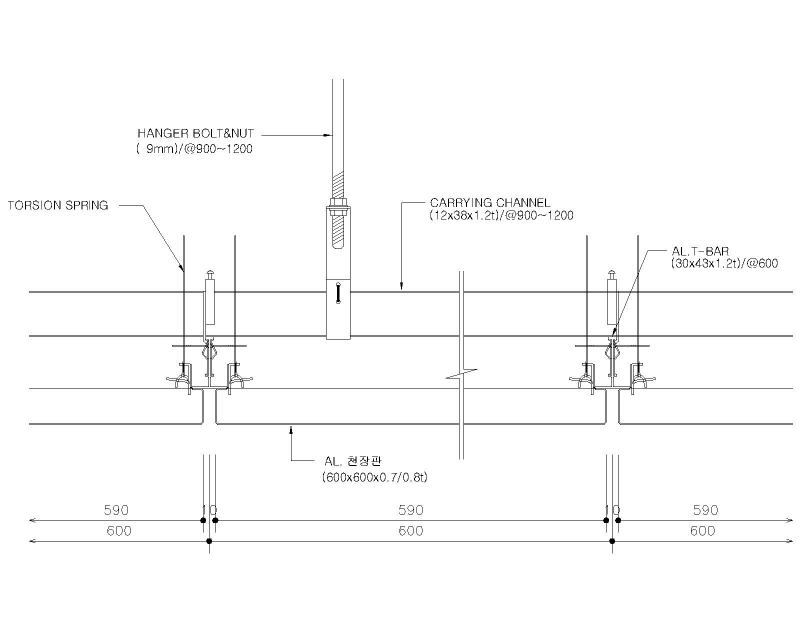

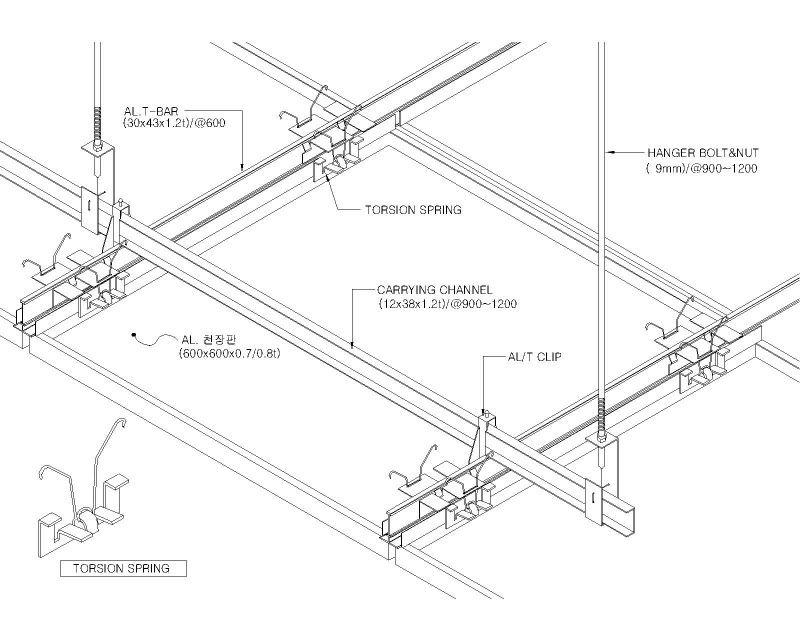

Composition of Al Torsion Panel (Flat type, slope type, down type)

- * Forming open joint without screw (beautiful exterior)

- * Securing quake-proof function in upward/downward left and right direction

- * Possible for attachment, detachment of each panel: securing possibility for checking

- * Connecting it to T-bar system which is universal light weight base support materials.

(1) Handling and storage of the product

- ① It shall be stored at a condition of relative humidity of 80% or less.

- ② To prevent any damage from water or moisture always keep it at dry and clean place.

- ③ Be careful not to damage corners

- ④ Maintain certain space from the wall surface and place spread sheet and then lay down water-proof sheet then preserve it.

(2) Environmental condition at the time of carrying out the works

- ① At the time of works temperature of 30℃ or less and relative humidity of 80% or less shall be maintained.

- ② The works shall be commenced after completion of joiners' works.

- ③ Before. during and after the works air-conditioners shall be operated so that proper level of indoors temperature and relative humidity are maintained.

- ④ The works shall be commenced after completion of all the papering and painting walls and ceiling.

(3) Caution at the time of carrying out works

- ① Pipe-laying and electric works shall be completed before installation of Al T-bar and then works shall be carried out.

- ② Check the connection of open panel and Al T-bar.

(4) Conditions for carrying out works

- ① The contractor for the works shall consult with the client with sufficient consideration of site conditions.

- ② While carrying out works at the time of appearance of any problems works shall be continued after sufficient consultation with the client.

- ③ As much as possible ceiling plan intended by the designer shall be observed.